Gold Coast Backflow Prevention Specialists – Ensuring Clean, Safe Water

Protecting your water supply from contamination is critical, and that’s where professional backflow testing comes in. At Local Plumbing & Gas Co., we install, maintain and test backflow prevention devices for residential, commercial, and industrial properties.

Backflow occurs when water flows in the reverse direction, potentially carrying polluted water or other contaminants back into your drinking water supply. This poses significant health risks, making backflow prevention essential for safeguarding your plumbing system. Regular device testing ensures your system complies with local regulations and keeps your water clean and safe.

Contact Us for Backflow Testing Gold Coast

Ensure your property’s water supply remains safe and compliant by scheduling your backflow testing Gold Coast with Local Plumbing & Gas Co. today. Our certified team is here to assist with all your backflow prevention needs. Call us at 1800 562 251 or contact us to book your backflow test and keep your water clean.

Comprehensive Backflow Prevention Services

Local Plumbing & Gas Co. provides a full range of Gold Coast plumbing services. We are experts in installing, maintaining, and testing backflow devices, ensuring your plumbing system operates safely and efficiently.

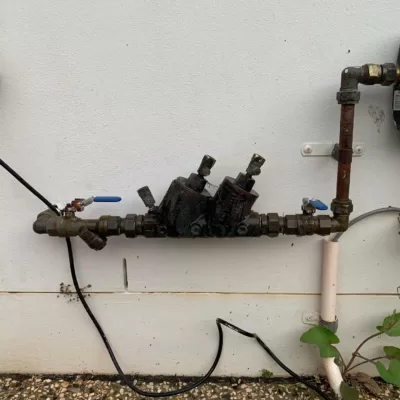

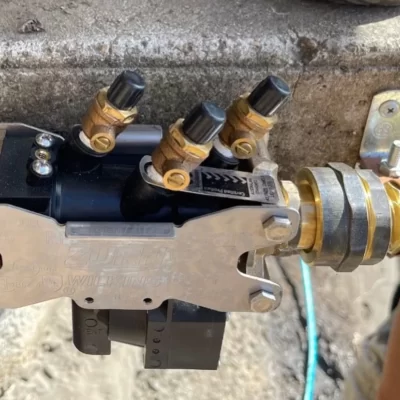

Backflow Prevention Device Installation

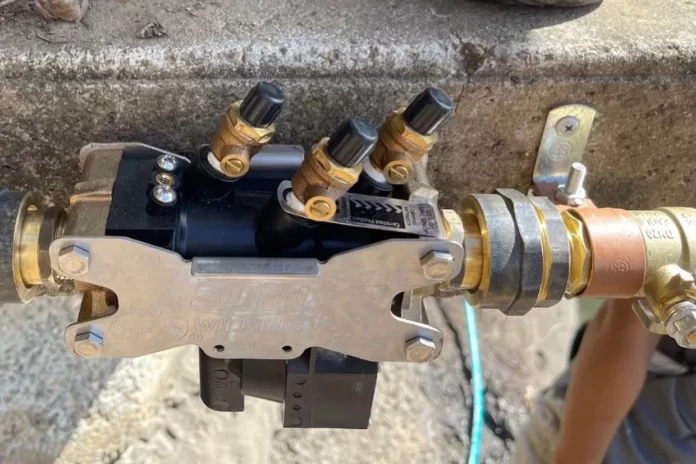

We install testable backflow prevention devices. These devices, such as RPZ valves and double check detector assemblies, are installed according to the highest safety standards.

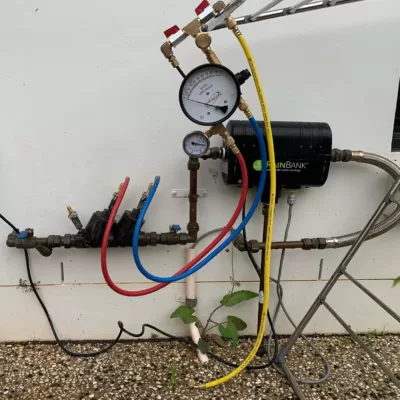

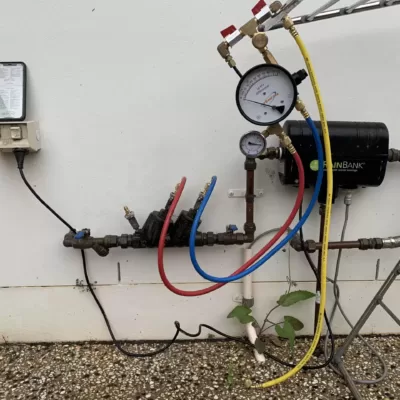

Backflow Testing

Our backflow testing service includes thorough inspections of your prevention devices to ensure they’re working effectively. We also perform annual backflow testing to maintain compliance with local regulations.

Repairs and Maintenance

If your device is faulty or needs repair, we offer comprehensive backflow prevention repairs and maintenance to keep your system running smoothly.

Why Backflow Testing is Crucial

Backflow testing is an essential step in protecting your drinking water. Whether you own a residential or commercial property, backflow prevention ensures your water remains clean and free from potential hazards entering the main supply.

- Protects Health: A functioning backflow device prevents cross-contamination between drinking and potentially polluted water, reducing the risk of waterborne diseases.

- Regulatory Compliance: Local councils require annual backflow testing to ensure your system meets safety standards. Staying compliant avoids penalties and keeps your property in line with regulations.

- Early Detection of Issues: Regular testing helps detect any malfunction in your backflow devices early, enabling timely repairs before serious issues arise.

- Peace of Mind: Knowing that your water system is safe provides you and your family peace of mind.

Backflow Prevention Device Testing and Compliance

As part of our commitment to providing reliable services, we ensure all devices are tested to meet local council and water authority guidelines. Our plumbers are certified in backflow testing and are qualified to issue the necessary compliance certificates. Annual testing protects your water and helps you remain compliant with legal requirements.

Backflow prevention devices should be tested annually to ensure they remain in top working condition. Our team uses advanced tools and techniques to conduct backflow tests efficiently and provide accurate results. You can ensure your system is safe from potential health risks by scheduling your annual backflow inspection with Local Plumbing & Gas Co.

Our Gold Coast Plumbing Service Area

We provide professional Gold Coast plumbing services across the region, including:

- Advancetown

- Arundel

- Ashmore

- Benowa

- Biggera Waters

- Bilinga

- Bonogin

- Broadbeach

- Broadbeach Waters

- Bundall

- Burleigh Heads

- Burleigh Waters

- Carrara

- Clear Island Waters

- Coombabah

- Coomera

- Coolangatta

- Currumbin Valley

- Currumbin Waters

- Elanora

- Gaven

- Helensvale

- Highland Park

- Hope Island

- Jacobs Well

- Labrador

- Main Beach

- Mermaid Beach

- Mermaid Waters

- Merrimac

- Miami

- Molendinar

- Mudgeeraba

- Nobby Beach

- Nerang

- Ormeau

- Ormeau Hills

- Oxenford

- Pacific Pines

- Palm Beach

- Paradise Point

- Parkwood

- Pimpama

- Reedy Creek

- Robina

- Runaway Bay

- Sanctuary Cove

- Southport

- Surfers Paradise

- Tugun

- Tweed Heads

- Upper Coomera

- Varsity Lakes

- Worongary

- + Many More!

Why Choose Local Plumbing & Gas Co.?

Licensed AND

Certified

Our plumbers are trained and certified to install and test backflow prevention devices, ensuring all work is completed to the highest standards.

Comprehensive Services

From installation to testing and repairs, we handle all aspects of backflow prevention to keep your water system safe and compliant.

Fast AND

Efficient

We provide prompt service with minimal disruption, offering same-day appointments when needed.

Guaranteed Compliance

We ensure that your property complies with all local regulations, giving you peace of mind and protecting your property’s value.

Plumbing Problems?

Get In Touch For a Fast Quote

Contact us today with your plumbing requirements, and our team will respond quickly to answer any questions and schedule a visit to provide a no-obligation quote.